China nylock hex nut wholesale supplier

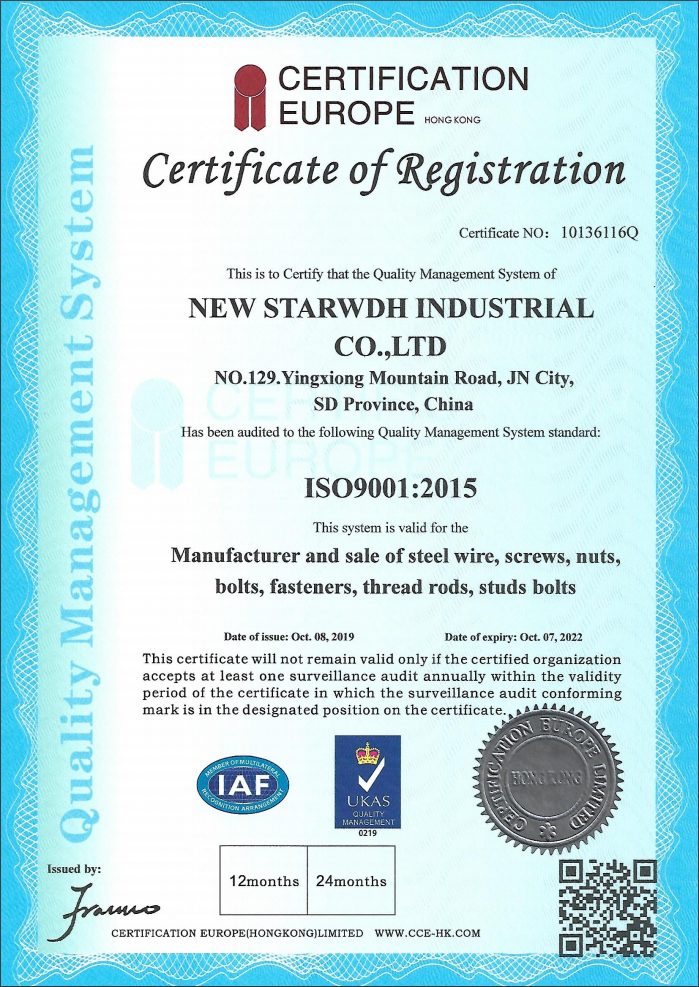

- NEWSTARWDH

- CHINA

- 7-35 DAYS

- 3000 TONS

Material: Carbon Steel, Alloy Steel, Stainless Steel

Standard: ASME/ANSI B18.2.2; DIN985, DIN982

Measurement system: INCH, Metric

Size: 1/8''-2''; M3-M48

Grade / Class: SAE J995 Gr.2, 5,8; CL4, 5, 6, 8, 10, 12

Thread: M, UNC, UNF

Finish: Black Oxide, Zinc Plated(Clear/Blue/Yellow/Black),H.D.G , Y.Z.P ,Plain, Nickel, Chrome.

Nylon Insert Nuts

Product Parameters

Description

Product name | Nylon Insert Nuts |

Place of origin | China(Mainland) |

Brand Name | NEWSTARWDH |

Port | Qingdao or according to requirement |

Delivery time | Normally in 7-35 days, according to quantity |

MOQ | 500kgs for each specification |

Mark | According to customer’s requirement |

OEM | Available |

Tip:Nylon lock nut how to use

A nut that relies on a nylon washer to lock it, called a nylon lock nut, is commonly referred to in the industry as a cap. Mainly used in conjunction with threaded screws or bolts, the nylon ring will be deformed after locking, and the gap between the joints at both ends will be filled, thereby locking.

1. Material strain hardening

When the material is cyclically loaded, there will be a phenomenon of "cyclic strain hardening" or "cyclic strain softening", that is, in the case of constant amplitude cyclic strain, the stress amplitude will increase or decrease as the number of cycles increases. After several cycles, the stress amplitude enters a cyclically stable state. The low cycle fatigue of the lock nut is carried out with a constant strain, and the strain hardening or softening of the thread will affect the maximum torque of the screw. The alloy steel used for the manufacture of the lock nut is a cyclic strain hardening material, and the hardening of the material increases the elastic restoring force FN of the thread piece, and the screwing torque increases.

2, low cycle fatigue

Low cycle fatigue means that the fatigue stress approaches or exceeds the yield limit of the material. The material has a certain amount of plastic deformation in each strain cycle. The life is generally in the range of 102 to several times 104. The fatigue curve is generally represented by the ε-N curve. . The finite element calculation results show that after the bolt is screwed into the lock nut, the root of the threaded piece has a large stress, and the surface of the surface layer is in a yielding state, while the central portion of the root of the threaded piece has a small strain and the strain condition is complicated. The region with high strain at the root of the thread is subjected to reciprocating loading, which is prone to low cycle fatigue, which reduces the pressure of the threaded piece and reduces the screwing torque.

3, friction coefficient

The friction angle is an important factor affecting the screwing torque. The existence of friction is the basis for the normal operation of the lock nut. When the lock nut is working, the contact surface has pressure and friction under the elastic restoring force of the thread piece. During repeated use, the contact surface is smoothed under the cyclic reciprocating friction, and the rough position and the corner are smoothed and smoothed. The coefficient of friction becomes smaller, which in turn reduces the maximum screwing torque of the nut.

4. Manufacturing and assembly

Due to limitations in manufacturing technology and accuracy, there are sharp corners on the edges of the threads or inconsistent dimensional fit between the parts. In the initial assembly, there may be some fluctuations or fluctuations in the screwing-in torque, which requires a certain number of running-in. In order to get a more accurate lock nut re-use characteristics.

5, closing value

After the geometric parameters of the material and the nut are determined, the change in the closing value has an important influence on the repeated use characteristics of the lock nut. When the closing value becomes large, the deformation of the thread piece is increased, the strain of the thread piece is increased, the strain hardening phenomenon is intensified, and the thread piece pressure FN is increased, which has a tendency to increase the screwing torque; on the other hand, the width of the thread piece is reduced. The total area of the thread piece is reduced, the frictional force with the bolt is reduced, the strain of the thread piece is increased, the low cycle fatigue performance is lowered, and the maximum screwing torque is reduced. Under the combined action of various factors, the maximum unscrewing torque is difficult to predict with the number of repeated uses, and it can only be observed through experiments.

Packaging Details:

A. Bulk in cartons(≤25KG)on wood pallet 36CTN/wood Pallet

B. Box + Carton + wood pallet , carton≤ 18kg , 48CTN/wood Pallet

C. According to customer special demand

Packing & Delivery

We also accept customization order according to your samples and drawings

If you have other questions or concerns, please feel free to contact us.