China stainless steel roofing screws customized quotes

- NEWSTARWDH

- CHINA

- 7-35 DAYS

- 3000 TONS

Product name: Roofing Screws

Application: Structural Steel; Metal Buliding; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Our advantage:

One-stop shopping;

High quality;

Competitive price;

Timely delivery;

Technical support;

Supply Material and Test Reports;

OEM

Samples for free

Roofing Screws

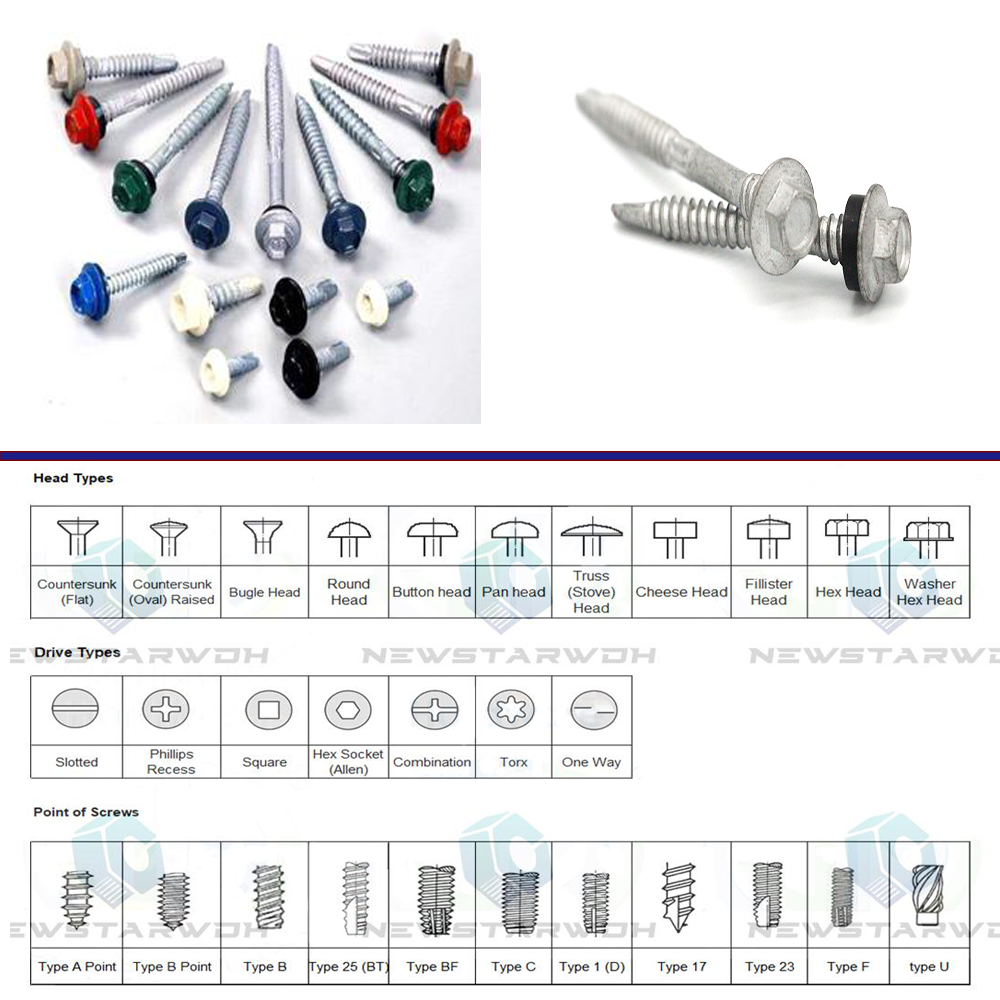

Product Parameters

Standard: | ASME B18.6, DIN7504K, DIN7504P,DIN7504N |

Size: | #4(2.8)-1/2" |

Material: | Carbon Steel, Alloy Steel, Stainless Steel |

Length: | 10-180mm (3/8”- 7”) |

Head type: | hex , hex washer |

Drive type: | hex socket |

Screw type: | BSD, CSD |

Finish: | Plain, Zinc Plated(Clear/Blue/Yellow/Black), Black oxide, Nickel, Chrome, H.D.G |

Packing: | bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand |

Application: | Structural Steel; Metal Buliding; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating |

Equipments: | Caliper, Go&No-go gauge, Tensile test machine, Hardness tester, Salt spraying tester, H.D.G thickness tester, 3D detector, Projector, Magnetic flaw detecter |

Supply Ability: | 5000 tons per month |

MinimumOrder: | 500kgs for each specification |

Trade Term: | FOB/CIF/CFR/CNF/EXW/DDU/DDP |

Our advantage: | One-stop shopping; OEM |

Notice: | Please lets know the Size, quantity, Material or Grade, surface, If it is special and Non-standard products, please supply the Drawing or Photos or Samples to us |

Description

Product name | metal roofing screws with rubber washer |

Place of origin | China(Mainland) |

Brand Name | NEWSTARWDH |

Port | Qingdao or according to requirement |

Delivery time | Normally in 7-35 days, according to quantity |

MOQ | 500kgs for each specification |

Mark | According to customer’s requirement |

OEM | Available |

Reason for roofing screw breakage:

1. Screw material problem, many installers like to use some screws with high hardness and easy to drill. In fact, most of these screws are high in carbon content. Drilling is easy, but lack of toughness and windy. Or when the PVC tile expands, it is easy to break.

2. Many small factory screws on the market are non-standard. The diameter of the screws is very small and there is very little galvanization on the outside. After the screws are screwed in, the screws will be ground or broken quickly, and the exposed parts are also exposed. It is easy to rust and cause the screw to break.

3. The installation method is not correct. The expansion coefficient of PVC tile and self-drilling screw is not the same. When the PVC tile is inflated and contracted, it may produce a large pulling force. The thicker the pulling force of the tile, the more likely it is to cause the tile screw to break or the tile to crack.

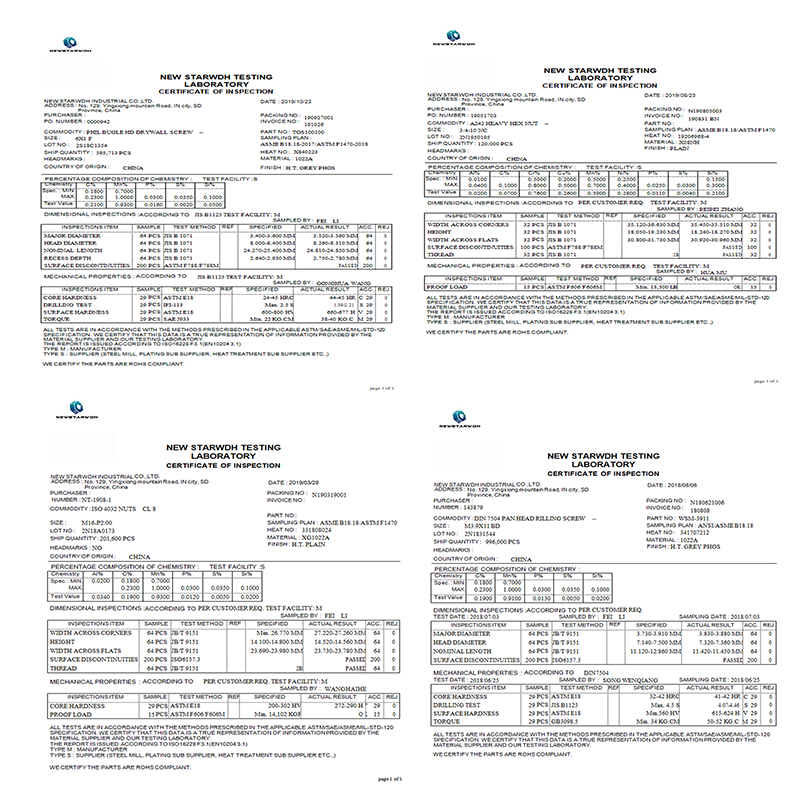

Quality control

our company strictly complies with ISO9001 system. All our products are subjected to strict test and inspection in each process by the workers periodically, starting from the raw materials delivered to the factory.

Test Report

If you require, the test report form the third part is available

Packaging Details:

A.

| SIZE | KGS/CTN | KGS/CTN |

| 24CTNS/PALLET | (11-22)KGS/CTN | 0.47 |

| 48CTNS/PALLET | (11-17)KGS/CTN | 0.35 |

| 36CTNS/PALLET | 15KGS/CTN | 0.33 |

| 30,40,50CTNS/PALLET | 15KGS/CTN | 0.35 |

| 36,48CTNS/PALLET | (10-22)KGS/CTN | 0.36 |

| 1CTN/PALLET | 803KGS/CTN | 4.55 |

| BAG | 25KGS/BAG |

B. According to customer special demand.

We also accept customization order according to your samples and drawings

If you have other questions or concerns, please feel free to contact us.