China mushroom head screw wholesale customized

- NEWSTARWDH

- CHINA

- 7-35 DAYS

- 3000 TONS

Product name: Mushroom machine Screws

Standard:ASME/ANSI B18.6 ,JIS B 1111

Size: #5 - 3/4"; M3 – M20

Material:Carbon Steel, Alloy Steel, Stainless Steel,

Length: 10-180mm (3/8”- 7”)

Head type: round mushroom

Drive type: Phil, slotted, Phil & slotted combination, hex socket, Pozl

Finish: Plain, Zinc Plated(Clear/Blue/Yellow/Black), Black oxide, Nickel, Chrome, H.D.G

Mushroom head machine screw

Product Parameters

Standard: | ASME/ANSI B18.6 ,JIS B 1111 |

Size: | #5 - 3/4"; M3 – M20 |

Material: | Carbon Steel, Alloy Steel, Stainless Steel, |

Length: | 10-180mm (3/8”- 7”) |

Head type: | round, mushroom |

Drive type: | Phil, slotted, Phil & slotted combination, Pozl |

Finish: | Plain, Zinc Plated(Clear/Blue/Yellow/Black), Black oxide, Nickel, Chrome, H.D.G |

Packing: | bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand |

Application: | Structural Steel; Metal Buliding; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating |

Equipments: | Caliper, Go&No-go gauge, Tensile test machine, Hardness tester, Salt spraying tester, H.D.G thickness tester, 3D detector, Projector, Magnetic flaw detecter |

Supply Ability: | 3000 tons per month |

MinimumOrder: | 500kgs for each specification |

Trade Term: | FOB/CIF/CFR/CNF/EXW/DDU/DDP |

Our advantage: | One-stop shopping; OEM |

Notice: | Please lets know the Size, quantity, Material or Grade, surface, If it is special and Non-standard products, please supply the Drawing or Photos or Samples to us |

Description

Product name | Mushroom head machine screw |

Place of origin | China(Mainland) |

Brand Name | NEWSTARWDH |

Port | Qingdao or according to requirement |

Delivery time | Normally in 7-35 days, according to quantity |

MOQ | 500kgs for each specification |

Mark | According to customer’s requirement |

OEM | Available |

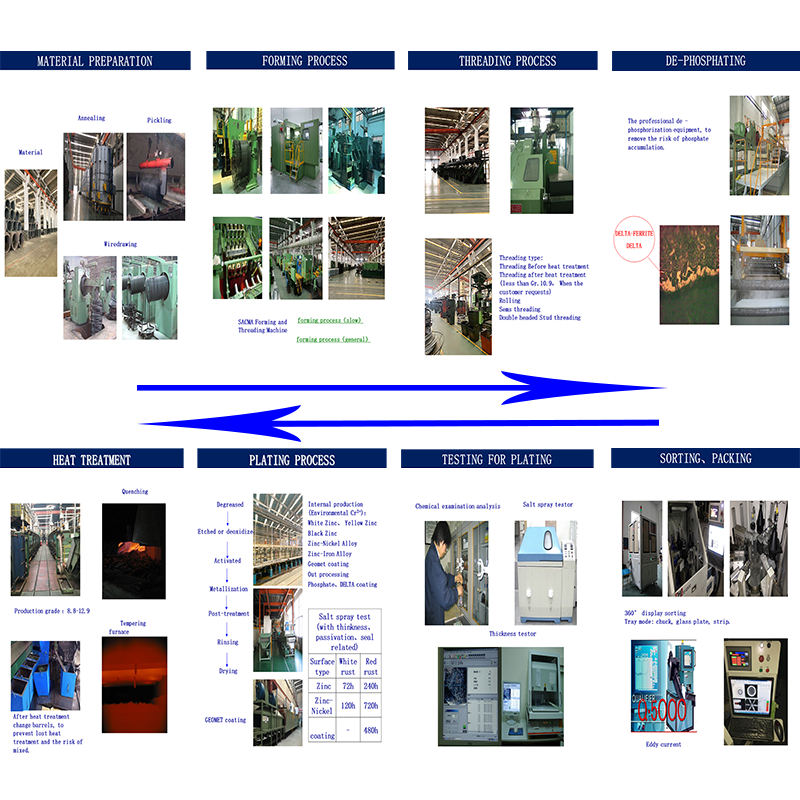

Cross recessed mushroom screw quality detection steps

First, first check the wire diameter of the screw wire of the cross groove mushroom, and check the material of the screw. Generally, the wire diameter of the screw is measured with a caliper, and the size of the wire diameter is the same as the size of the order.

second, detecting these, it is detected during the production process. Starting from the head of the screw, determine the head size, head-to-edge, diagonal, cross groove depth, screw tolerance range, and so on. These are all detected with a caliper.

Then it is the detection of all aspects of tooth decay, the main thing is whether the thread can pass the through stop gauge, the screw thread can pass the regulation, and the regulation is stopped.

Again, it is the problem of electroplating measurement. After electroplating, is it in line with environmental requirements and can pass the time required for salt spray? The tool has an environmental testing machine and a salt spray test machine.

In short, in the production and sales of Phillips screw, the tools necessary to use the necessary quality of the test screw are definitely necessary. The summary is summarized as follows: caliper, hardness tester, salt spray machine, environmental test machine, pass regulation, etc.

Packaging Details:

A.

| SIZE | KGS/CTN | KGS/CTN |

| 24CTNS/PALLET | (11-22)KGS/CTN | 0.47 |

| 48CTNS/PALLET | (11-17)KGS/CTN | 0.35 |

| 36CTNS/PALLET | 15KGS/CTN | 0.33 |

| 30,40,50CTNS/PALLET | 15KGS/CTN | 0.35 |

| 36,48CTNS/PALLET | (10-22)KGS/CTN | 0.36 |

| 1CTN/PALLET | 803KGS/CTN | 4.55 |

| BAG | 25KGS/BAG |

B. According to customer special demand.

We also accept customization order according to your samples and drawings

If you have other questions or concerns, please feel free to contact us.