China self tapping screws customized quotes

- NEWSTARWDH

- CHINA

- 7-35 DAYS

- 5000 TONS

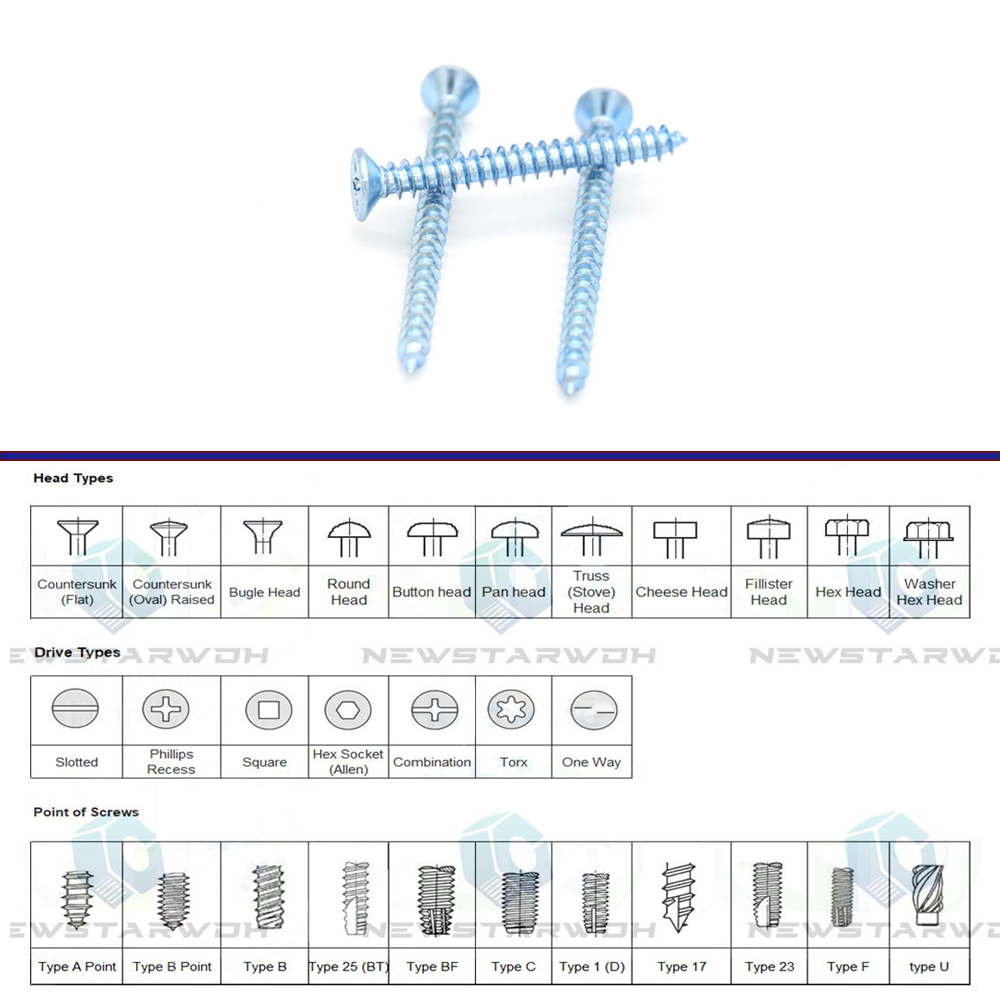

Standard:ASME B18.6, DIN7972, DIN7973 , DIN7982, DIN7983,ISO7050

Size:#4(2.8)-1/2"

Length:10-180mm (3/8”- 7”)

Head type: flat

Drive type:Phil, slotted, Phil & slotted combination, pozi

Screw type:AB, B, BP, BF, BT, C, D, F, G, T, U

Material:Carbon steel C1018, C1022, CH22A (+ heat treatment), SS304, SS316, SS410

Thread:M, UNC, UNF

Finish:Plain, Zinc Plated(Clear/Blue/Yellow/Black), Black oxide, Nickel, Chrome, H.D.G

Cross Recessed Countersunk Head Tapping Screws

Product Parameters

Standard: | ASME B18.6, DIN7972, DIN7973 , DIN7982, DIN7983,ISO7050 |

Size: | #4(2.8)-1/2" |

Length: | 10-180mm (3/8”- 7”) |

Head type: | countersunk head |

Drive type: | phil , pozi , cross recessed |

Screw type: | AB, B, BP, BF, BT, C, D, F, G, T, U |

Material: | Carbon steel C1018, C1022, CH22A (+ heat treatment), |

Thread: | M, UNC, UNF |

Finish: | Plain, Zinc Plated(Clear/Blue/Yellow/Black), Black oxide, Nickel, Chrome, H.D.G |

Packing: | bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand |

Application: | · Structural Steel; Metal Buliding; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating |

Equipments: | · Caliper, Go&No-go gauge,Tensile test machine, Hardness tester, Salt spraying tester, H.D.G thickness tester, 3D detector, Projector, Magnetic flaw detecter |

Supply Ability: | 5000 tons per month |

MinimumOrder: | 500kgs for each specification |

Trade Term: | FOB/CIF/CFR/CNF/EXW/DDU/DDP |

Our advantage: | One-stop shopping; High quality; Competitive price; Timely delivery; Technical support; Supply Material and Test Reports; OEM Samples for free |

Notice: | Please lets know the Size, quantity, Material or Grade, surface, If it is special and Non-standard products, please supply the Drawing or Photos or Samples to us |

feature

(1) Super corrosion resistance, cross recessed countersunk head tapping screws have resistance to air, water, acid, alkali salt or other corrosive media, and are often used in medical, chemical and other areas requiring corrosion resistance.

(2) The material structure is stable, and its austenitic structure can be maintained at various temperatures without phase change.

(3) Non-magnetic, non-magnetic under normal conditions, slightly magnetic after cold work, the values of magnetic permeability μr are as follows: A2: μr≈1.8, A4≈1.015, A4L≈1.005.

Notices

1, choose the right product

(1) Before using, confirm whether the mechanical properties of the product meet the customer's requirements (such as the tensile strength of the bolt and the safety load of the nut).

(2) The length of the bolt should be selected properly, and the 1-2 tooth pitches of the nut should be exposed after tightening.

(3) The thread of the product should be kept clean before use.

2, how to use fasteners correctly

(1) When tightening, please pay attention to the direction of the wrench's force to coincide with the screw axis, do not tilt.

(2) During the tightening process, the force should not exceed the safe torque and be uniform. Use a torque wrench or a sleeve as much as possible.

(3) If the locking speed is too fast, it will cause locking. It is not recommended to use electric or pneumatic wrench.

(4) Keep the thread clean. To ensure smooth cooperation between the screw and the nut, it is recommended to put the product in a clean container and do not place it at will.

3, maintenance standards

(1) If the screws and nuts under the disassembly are slightly damaged, apply the die and tap repair.

(2) The removed and repaired screws and nuts should be maintained in the form of oil bubbles or lubricating oil, and placed neatly according to specifications and model usage.